More Handles Technical guides: “My Door Handle grub screws keep falling out” How to resolve this

13 October 2019 :: How To Guides

More Handles Technical guides: “My Door Handle grub screws keep falling out” How to resolve this

Architectural Ironmongery can be a confusing place - filled with different terminology and jargon that can quickly become confusing. The More Handles Technical guides series of articles aims to break down confusing industry jargon, and help explain the differences between similar items where confusion can easily occur.

“My grub screws keep falling out, how can I fix this problem?” Is a question we are sometimes asked. Let's take a look at what causes this and how to resolve this problem, as well as asking what type of grub screw is best to use, and actually why it is that we use grub screws.

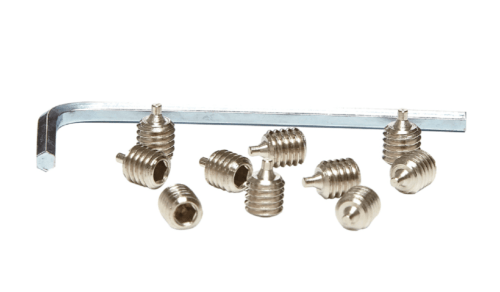

A grub screw, also sometimes known as a 'set-screw' in North America and other countries, is actually rather confusingly a type of bolt. This is because it is grooved, so that it may be threaded into a pre-existing threaded hole, rather than driven into a surface, like a traditional screw would be.

So, what function does the grub screw perform? Well, the grub screw is generally used to secure an item against another item, without the use of a nut. This is important, because the ability to secure without a nut makes the grub screw very versatile, and means that a grub screw can be used in applications that require a very small and unobtrusive fixing. This is useful in situations where a traditional nut and bolt fixing would either obstruct the operation of an item, or be aesthetically unacceptable.

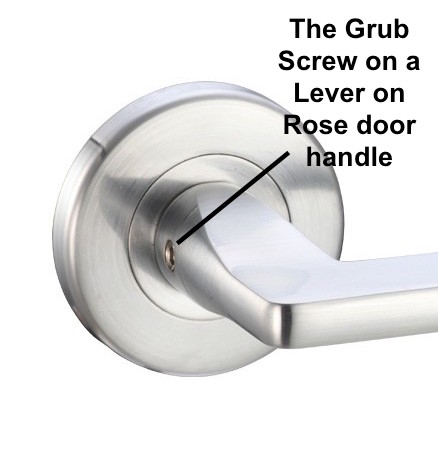

Grub screws perform a great many different roles in various industries, such as in mechanics and engineering, where metal surfaces rub together and must not be obstructed by screw or bolt heads. In the architectural ironmongery industry, the most common purpose of the grub screw is to attach a door knob or door handle directly to the spindle shaft. The way this works is as follows: There is a threaded hole tapped into the neck of a lever handle or door knob. The hole extends right through into the square locator recess at the rear of the door handle. The spindle is then pushed into the locator hole, positioning the door handlein its place on the door. Then, the grub screw is threaded into the tapped hole, and impacts onto the spindle, creating lateral compressional or ‘clamping’ force through the bottom tip of the grub screw that projects through the tapped hole. This pressure holds the door handle or door knob in place on the spindle shaft.

In times past, grub screws on door handles utilised a raised rounded,

commonly slotted head. As part of a major early 20th Century drive within industry to improve safety for workers, the modern ‘headless’ grub screw was developed. These days, grub screws are almost always headless, which means that the grub screw body is fully threaded and has no head projecting past the diameter of the screw. Almost all modern grub screws are operated by way of an internal socket drive such and a hexagonal Allen (hex) socket, or a Torx socket. The advantage to using a headless grub screw is that there is no sharp protruding head to catch fingers on. Another advantage is that Torx and Hex heads facilitate far more torque to be applied before the head becomes malformed through excessive application of torque. This means during fitting, you can get a grub screw much tighter than its raised-head counterpart. Except for few very reproduction antique lines of door furniture, all of our door handles and door knobs utilize a hexagonal Allen key drive in their grub screws for the most secure fixing possible.

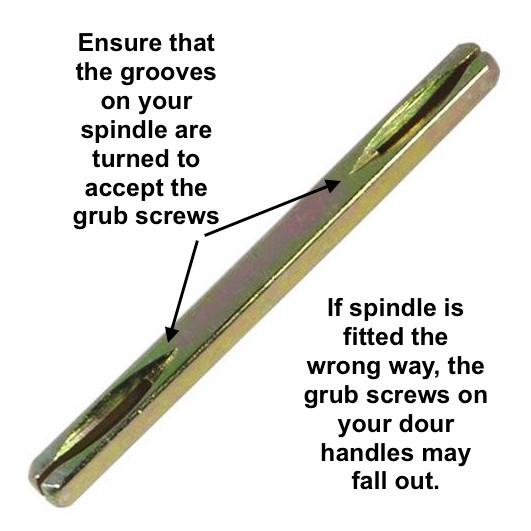

The use of an Allen hex drive grub screw against a spindle creates a strong grip, but to make this grip even more secure, we supply most of our door handles with a ‘grooved’ or ‘slotted’ spindle. The Grooved spindle is a special type of spindle which is cut right through at either end, and has a grooved out ‘trough’ surrounding the cut. The purpose of the groove is to accept the grub screw and locates into the groove. The grub screw then wedges into the groove and opens up the spindle, creating a lateral pressure and grips in to the door handle or door knob. This creates an extremely secure fixing.

So, what if your grub screws keep falling out? On occasion, we are asked for advice from a customer whose grub screws seem to unthread themselves, and drop out of their door handles onto the floor. This can result in the door handle coming loose off the door. Why does this occur? Well, the most common cause of this is that the spindles have been installed the wrong way up, so that the grooved or slotted face is facing away from the grub screw. When this occurs, the grub screw cannot bite into the spindle, and will work itself loose over time, eventually dropping out onto the floor. The problem of grub screws falling out is irritating, but can almost always be cured very easily.

To fix the problem, you will need to loosen the grub screws, remove the screws or bolts on the door handles, and remove the door handle on one side. Then, pull out the spindle. You will most likely find that the grooved face of the spindle is facing away from the grub screw point. Simply turn the spindle so that the grub screw can bite into the groove, re-attach the door handles, tighten the grub screws back up, and there you have it – The problem of grub screws dropping out should be solved! If you need any help or further advice regarding grub screws or would like to discuss your requirements further, then please do not hesitate to contact our helpful experts at More Handles HQ in Carlisle! We will be happy to discuss any other issues with grub screws and spindles you may have, and offer solutions to help.

Call us on 01228 516 516 or email us at sales@morehandles.co.uk

WEB - morehandles.co.uk